Introduction to Sorption Global Technologies

The Problem with Traditional Methods

- Incomplete Recovery: Traditional methods often fail to recover all the spilled oil, leaving substantial amounts in the environment.

- Environmental Impact: Dispersants break oil into smaller droplets but can introduce toxic chemicals into marine ecosystems, affecting wildlife and human health.

- High Operational Costs: Booms and skimmers require extensive manual labor and logistical coordination, making them expensive to deploy and maintain.

- Time-consuming: These methods can be slow and fail to prevent oil’s immediate spread and infiltration into sensitive coastal areas.

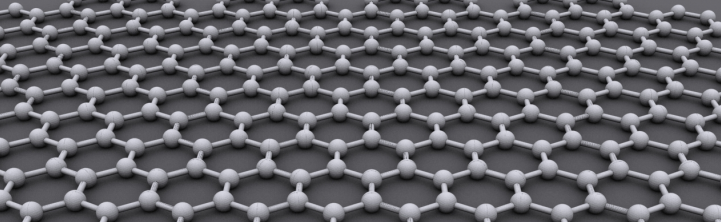

Graphene-Based Sorption Systems

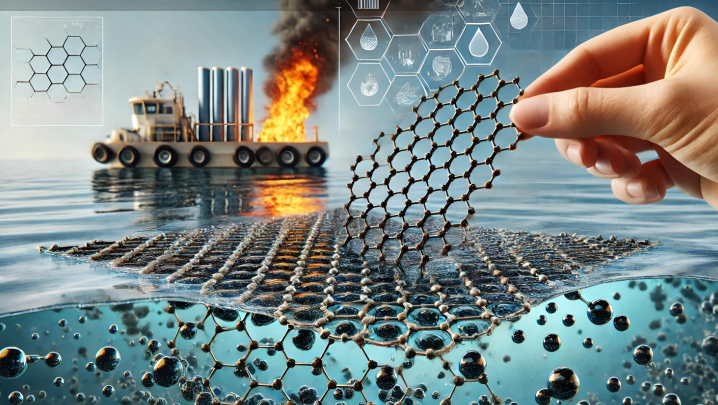

How It Works

- Adsorption:Graphene’s large surface area allows it to adsorb oil rapidly and in large quantities (Chen et al., 2022).

- Separation: Graphene’s hydrophobic nature repels water while adsorbing oil, facilitating efficient separation (MDPI, 2022).

- Reusability:After adsorption, the oil can be extracted from the graphene material, allowing the sorbents to be reused multiple times (Environmental Science and Pollution Research, 2023).

Effectiveness and Uniqueness

- High Adsorption Capacity:Graphene sorbents can adsorb up to 86 times their own weight in oil, making them significantly more efficient than traditional materials (Chen et al., 2022).

- Rapid Oil Removal:Graphene’s unique properties allow for quick and continuous oil removal, which is critical for minimizing environmental damage (Springer, 2022).

- Reusability:Graphene-based sorbents can be regenerated and reused multiple times without significant performance loss, providing long-term cost savings and reducing waste (Environmental Science and Pollution Research, 2023).

- Environmental Friendliness:Unlike chemical dispersants, graphene is non-toxic and does not introduce harmful substances into the marine environment (Nanomaterials, 2022).

Environmental and Economic Benefits

Environmental Benefits

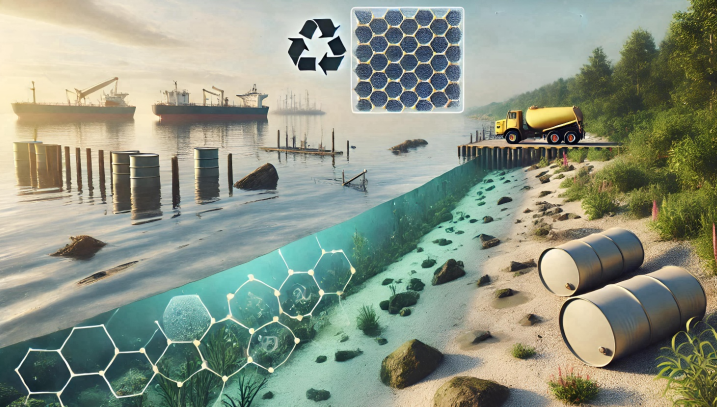

- Reduced Ecological Impact: Rapid and efficient oil removal minimizes the exposure of marine and coastal ecosystems to harmful hydrocarbons.

- Non-Toxicity: Graphene is inherently non-toxic, ensuring cleanup efforts do not introduce additional pollutants.

- Sustainability: Graphene sorbents’ reusability supports sustainable cleanup practices, reducing the need for continuous production and disposal of cleanup materials.

Economic Benefits

- Cost Savings: Graphene sorbents’ high adsorption capacity and reusability lead to significant cost reductions in oil spill cleanup operations.

- Resource Recovery: Recovering and reusing absorbed oil adds economic value, turning waste into a resource.

- Long-Term Value: Investing in advanced technologies like graphene-based systems can reduce long-term environmental damage and remediation costs.

Future of Oil Spill Cleanup

- Nanotechnology:Continued advancements in nanomaterials are expected to enhance the efficiency and effectiveness of oil spill cleanup. For instance, semiconductor-based sorbents that leverage photothermal effects for oil adsorption are being developed (Huang et al., 2024).

- Hybrid Systems:Combining different advanced materials and technologies can lead to hybrid systems that offer synergistic benefits, further improving cleanup capabilities.

- Automation and AI:Integrating automation and artificial intelligence in deployment and monitoring can optimize the response to oil spills, making operations faster and more precise (Springer, 2022).

- Regulatory Support: As governments and regulatory bodies recognize the benefits of advanced cleanup technologies, supportive policies and funding can accelerate their adoption and development.

Developing and deploying innovative oil spill cleanup technologies, particularly graphene-based sorption systems, represent a significant leap forward in addressing oil spills’ environmental and economic challenges. Sorption Global Technologies is leading the way with its cutting-edge solutions, demonstrating that effective, efficient, and sustainable oil spill remediation is possible and within reach. Continued research, investment, and collaboration will be key to advancing these technologies and ensuring a cleaner, safer future for our oceans.

References

Chen, X., Gao, Y., & Dai, L. (2022). 3D graphene-based materials for energy storage. Current Opinion in Colloid & Interface Science, 20, 429–438.

Georgakilas, V., Perman, J. A., Tucek, J., & Zboril, R. (2015). Broad family of carbon nanoallotropes: Classification, chemistry, and applications of fullerenes, carbon dots, nanotubes, graphene, nanodiamonds, and combined superstructures. Chemical Reviews, 115(11), 4744-4822.

MDPI. (2022). Recent developments and advancements in graphene-based technologies for oil spill cleanup and oil–water separation processes. Nanomaterials, 12(1), 87. https://doi.org/10.3390/nano12010087

Environmental Science and Pollution Research. (2023). 3D graphene-based nanostructured materials as sorbents for cleaning oil spills and for the removal of dyes and miscellaneous pollutants present in water. Environmental Science and Pollution Research. https://doi.org/10.1007/s11356-022-23212-0

Developing and deploying innovative oil spill cleanup technologies, particularly graphene-based sorption systems, represent a significant leap forward in addressing oil spills’ environmental and economic challenges. Sorption Global Technologies is leading the way with its cutting-edge solutions, demonstrating that effective, efficient, and sustainable oil spill remediation is possible and within reach. Continued research, investment, and collaboration will be key to advancing these technologies and ensuring a cleaner, safer future for our oceans.

If you want to learn more about our graphene-based sorption systems or want to see a demonstration, please contact us. Our team is dedicated to providing innovative solutions to protect our environment and support sustainable practices.